SHIP CUTTERS

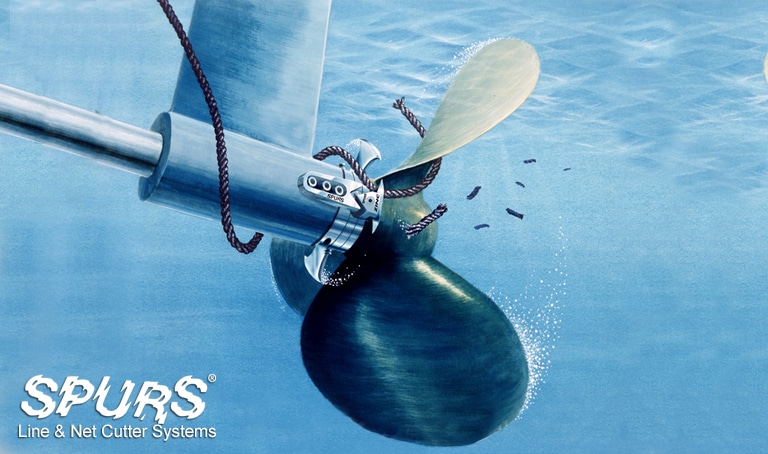

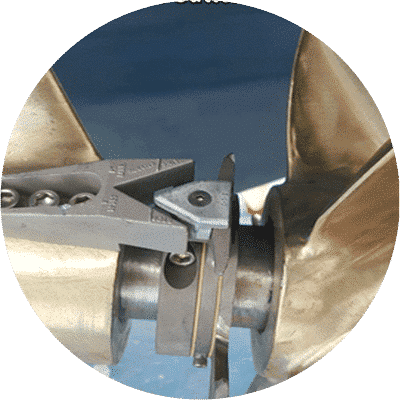

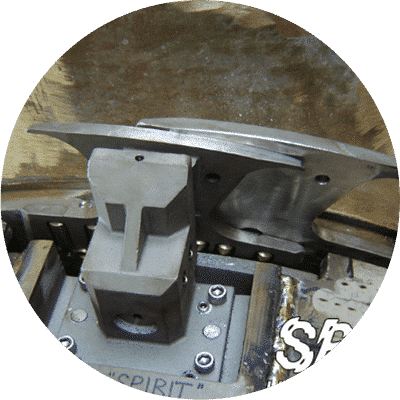

Spurs Line Cutter Systems use the propeller’s rotation and inertial force to power the cutting action. As the offending line enters the propeller vortex, it is wound toward the propeller hub. (NOTE: It is at this point that, without SPURS installed, the line would wind itself tighter and tighter, entering into the space between propeller hub and rope guard, where it can damage the oil seals.) Instead, the line is engaged by the rotating cutter blades and delivered to the stationary cutter blade. The sudden resistance sensed by the stationary cutter forces a cam action which causes the blade to be pushed outward, meeting the rotating blade and severing the obstruction.

The cutting force increases in direct proportion to the resistance sensed by the stationary cutter assembly. This shearing action means that the cutting blades never actually come into contact with each other. Hydrophilic and bronze surface bearings maintain precise cutter positioning when a resistance occurs. With each rotation, the cutters pass each other gliding on a thin lubricating film of water or within a few thousandths of each other, thus avoiding surface wear during long passages. The stationary cutter centers itself in the cutter guides as it passes through with each revolution of the propeller.

Français

Français  English

English