SPURS | Line & Net Cutters

SPURSLine & Net Cutters

Protect Your Propulsion System – Eliminate the Risk of Entanglement

SPURS is specifically designed to prevent ropes, fishing lines, nets, or debris from wrapping around your propeller shaft and damaging the shaft seals.

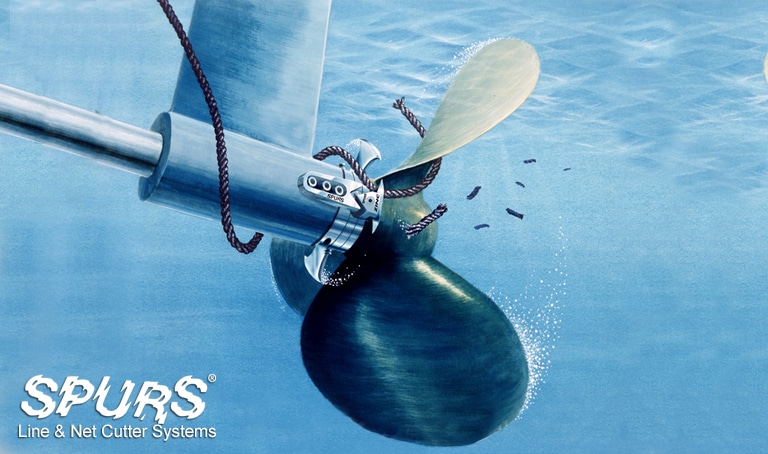

When a vessel is underway, the rotating propeller creates a natural suction that draws in any lines or nets it encounters. These become tightly wound around the shaft, causing friction and pressure that can severely damage shaft seals—resulting in oil leaks or, in worst-case scenarios, critical breakdowns that immobilize the vessel.

How It Works

SPURS features a set of two or more rotating blades mounted in front of the propeller, combined with a fixed blade attached to the shaft strut or stern tube. As the propeller rotates—whether in forward or reverse—any foreign object caught in its path is instantly sheared by the scissors-like action of the SPURS system.

This immediate cutting action eliminates the possibility of entanglement, keeping your propulsion system clear and fully operational.

A Must-Have for Leisure Boaters and Professionals Alike

Whether you’re a recreational sailor or a maritime professional, the safety of your vessel and its passengers is always a top priority. But there’s another growing concern: marine pollution.

Traditional oil-lubricated stuffing boxes or shaft seals are not only vulnerable but also hazardous to the environment if damaged. More and more captains are turning to SPURS as a reliable, eco-conscious solution to avoid both mechanical failures and environmental risks.

Models

Shaft Mounted

MOTORBOATS

For shafts from 20 to 255 mm

3/4″ to 10″

Ship Propeller Mounted

LARGE VESSELS

For shafts from 300 mm or 12″ and up (no upper limit)

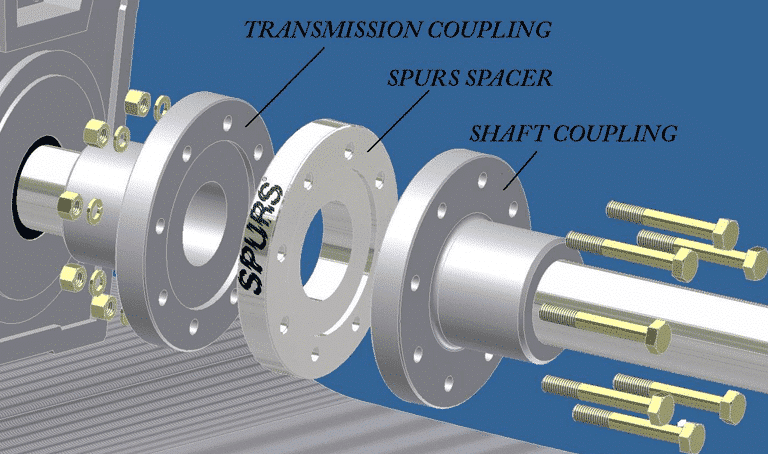

TRANSMISSION SPACER

Extend the propeller shaft

Why Choose the SPURS Line Cutter?

Eco-Friendly and Legally Compliant

With the growing amount of drifting nets and marine debris, the risk of entanglement around your propeller shaft is increasing dramatically. In many cases, this leads to continuous oil leakage, causing pollution for which you are legally responsible.

By installing a SPURS line cutter, you effectively prevent:

- Shaft and seal damage

- Vessel immobilization

- Expensive environmental pollution incidents

⚠️ The 1990 Oil Pollution Act enforces heavy penalties for polluters. Authorities such as the Coast Guard can order your vessel to stop operations until repairs are made and compliance is ensured.

Protecting the ocean means protecting your vessel, your business, and your legal standing.

Fuel Efficiency and Performance

Beyond mechanical risks, a rope or net caught in the propeller significantly reduces its efficiency.

A fouled or restricted propeller creates drag, causes vibrations, and puts additional strain on the engine.

The result:

- Increased fuel consumption

- Reduced propulsion performance

- Higher operational and environmental costs

With SPURS, your propeller stays clean and unobstructed—ensuring optimal performance and fuel efficiency.

Proven and Trusted for Over 30 Years

For over three decades, SPURS has been protecting all types of vessels, from recreational sailboats to large military and commercial ships.

Today, more than 500 vessels worldwide are equipped with the SPURS line cutter system.

Trusted by some of the most demanding maritime institutions:

- US Coast Guard

- US Navy

- British Royal Navy

- Cruise ships

- Tankers

- Commercial and research fleets

A proven solution trusted by professionals, even in the harshest sea conditions.

Peace of Mind at Sea

SPURS line cutters provide protection before problems even start—cutting through ropes, nets, and debris before they can tighten around the shaft, wrap the propeller, or damage the drivetrain.

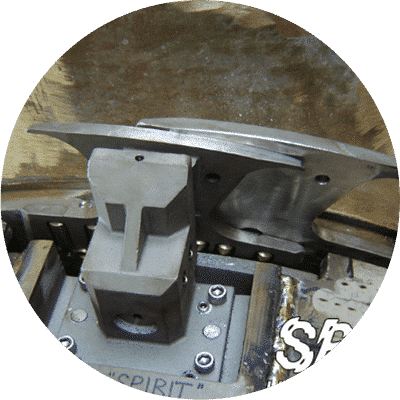

After every installation and before launch, a live test is conducted to ensure proper operation.

This test validates:

- Blade alignment and positioning

- Smooth and effective cutting performance

- Immediate readiness for safe operation

Sail with confidence—your propulsion system is protected from the start.

Shafts, Thrusters & Pods

The SPURS line cutter can be installed on any type of propulsion system, regardless of size:

- Propeller shafts

- Thrusters

- Pods

- Fixed or variable-pitch propellers

- And any other propulsion-related component.

The most common damage results from premature wear of seals and bearings, caused by rope abrasion or abnormal water ingress.

Protect your vessel from costly damage by installing a SPURS line cutter.

How the SPURS Line Cutter Works

SPURS Line Cutter for Commercial Vessels

With the growing amount of drifting nets and marine debris, vessels are increasingly at risk of entanglement along the propeller shaft.

In many cases, this leads to continuous oil leakage—pollution for which the shipowner is fully liable.

The SPURS line cutter is designed to prevent:

Costly mechanical failures

Vessel immobilization at sea or in port

Marine pollution incidents that can trigger legal and financial consequences

⚠️ Under the 1990 Oil Pollution Act, polluters face strict penalties.

Coast Guards and other maritime authorities may order the immediate stop of the vessel and demand repairs before operations can resume.

SPURS offers proven, reliable protection—for your vessel, your crew, and the environment.

SPURS Line Cutter for Propeller Shafts

Sharing the same proven design as the ship-grade SPURS system, the SPURS for propeller shafts cuts through ropes and lines before they can wrap around the hub or interfere with the drivetrain.

Debris is naturally drawn toward the center by the propeller’s rotation—where it is swiftly severed by the SPURS cutting blades.

This model mounts directly onto the propeller shaft, harnessing the full torque of the engine.

Equipped with Kevlar/Teflon bearings, it ensures the same precise alignment and cutting efficiency as our systems designed for larger vessels.

A compact and dependable solution for conventional shaft lines—without compromising performance.

SPURS Line Cutter

Protecting vessels from drifting nets and ropes since 1981.

Trusted worldwide for performance, reliability, and peace of mind at sea.

Global Deployment

SPURS line cutters are trusted worldwide, serving both commercial and recreational vessels with proven performance and durability.

Installed on:

- US Coast Guard (USCG)

- US Navy

- Canadian Coast Guard

- RNLI – Royal National Lifeboat Institution (UK)

- Pilot boats

- And over 100,000 vessels around the globe

SPURS: the trusted standard across all seas.

Every Voyage is Safer

With SPURS line cutter systems installed on your vessel, you sail with peace of mind—protected from entanglement, damage, and environmental hazards.

A proven and silent guardian for every journey at sea.

Information Request

Looking for a quote or have questions about SPURS line cutters?

Simply fill out the form below, and one of our experts will get back to you promptly.

You can also contact us directly at +33 (0)4 94 53 27 70.

*Fields marked with an asterisk are required.

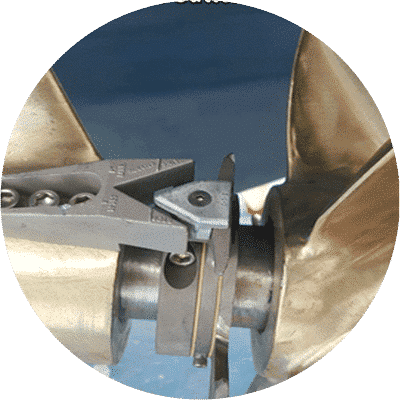

SPURS Line Cutter Mounted on Propeller Shaft

What makes SPURS so effective is the “screw-like” action created by the rotating propeller.

This motion pulls ropes, nets, seaweed, and debris directly into the cutting blades.

The scissor action between the rotating blades and the stationary blade prevents any wrapping or constriction around the propeller shaft.

Key Benefits:

- Instantly slices through ropes, nets, and seaweed

- Eliminates the need to dive in hazardous conditions

- Prevents propulsion failure and costly downtime

- Avoids the need for towing or emergency assistance

- Protects shaft, coupling, shaft bracket, and drivetrain

- Prevents bearing damage due to overheating

- Fully effective in both forward and reverse motion

- Available for shafts from 20 mm to 255 mm (3/4″ to 10″)

- Built from marine-grade stainless steel for maximum durability

Don’t leave the dock without SPURS protection.

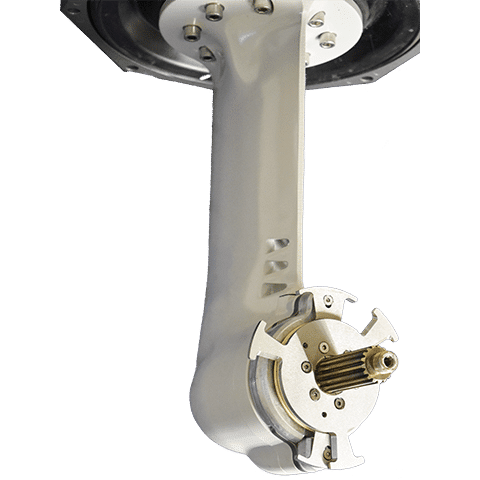

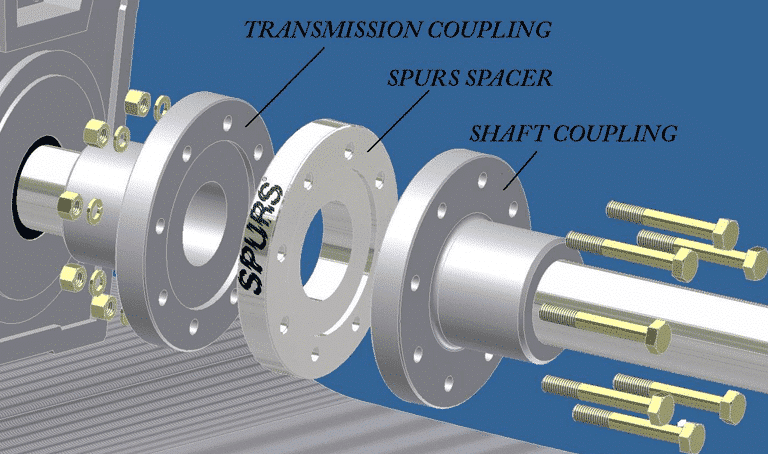

SPURS Spacer

SPURS is globally recognized for the quality and effectiveness of its line cutter systems. To meet growing demand and adapt to a wide range of propulsion setups, SPURS has developed a dedicated line of precision spacers.

These spacers are installed between the shaft coupling flanges:

between the propeller shaft and the gearbox.

- Standard thickness: 1 inch

- Precision tolerance: .001″

- Also available custom-made to match specific technical requirements

The spacer is a simple and effective solution that ensures correct SPURS positioning when additional clearance is needed between components.

A key accessory for a secure and precise installation.

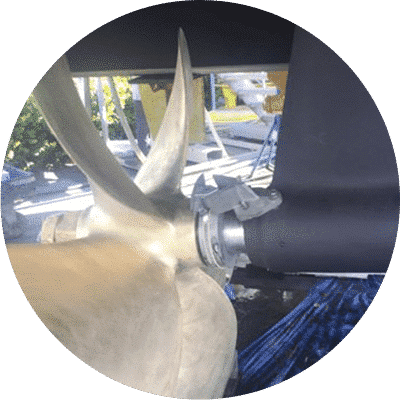

SPURS Line Cutter Mounted on Propeller Hub

Specifically designed for medium and large vessels, this SPURS model mounts directly on the propeller hub, offering instant protection against entanglement and its costly consequences.

It protects your ship from: Seal ruptures, Oil leaks, Environmental , pollution and Unexpected downtime and repair costs.

Key Features:

- Effectively cuts ropes, lines, and nets

- Prevents oil leakage caused by line entanglement

- Reduces the need for towing or emergency assistance

- Fits propeller hubs from 300 mm (12″) and up

- Made entirely of marine-grade stainless steel for long-lasting performance

Don’t leave the dock without SPURS protection.