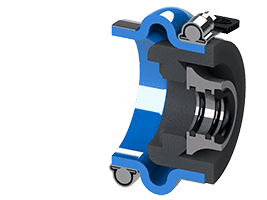

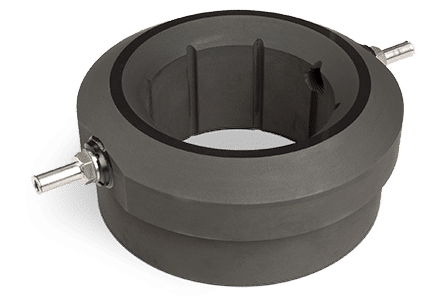

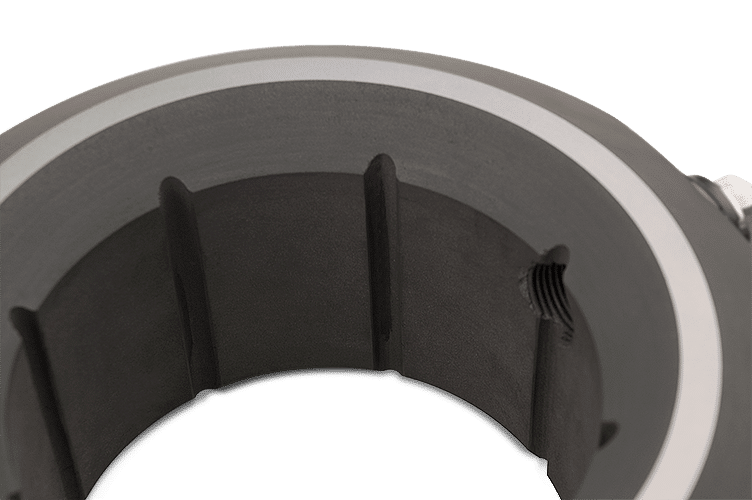

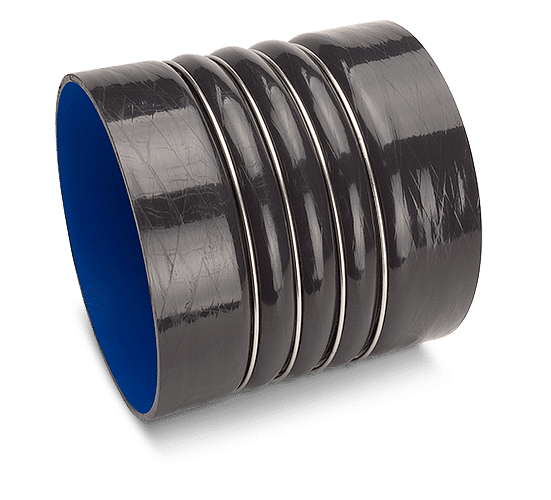

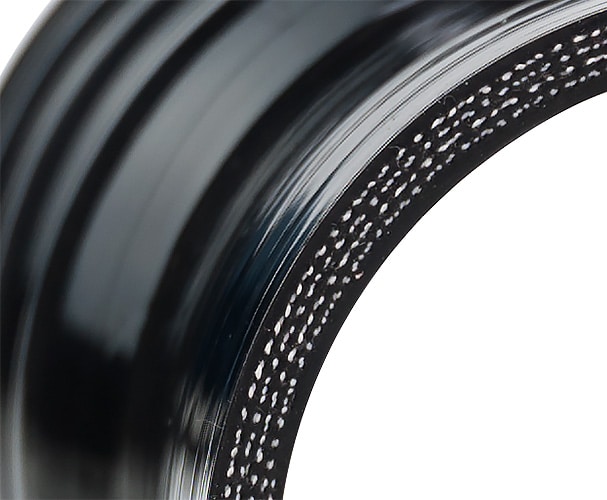

Carbon-graphite is a versatile seal face material used with mating rings of harder material. The PSS carbon has superior wear characteristics and broad chemical resistance.

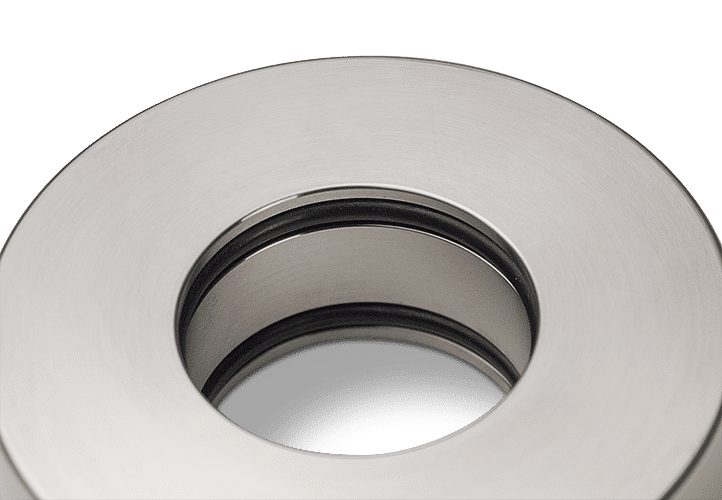

The face of the carbon is finished to a flatness of 4 helium light bands (measured .000044" of variation over entire lapped surface). The grade of carbon used in the PSS has an operating temperature over 500°F (+260°C), and cannot melt if the seal runs dry, unlike a rubber lip seal or plastic face seal.

The high density of the carbon greatly increases the longevity and wear resistance. Over 40,000 hours (over 4.5 years of continuous operation) has been recorded on the same original component. The carbon graphite stator should not need to be replaced under normal operating conditions.

Français

Français  English

English