Every year, biofouling is estimated to add $60-100 billion to commercial shipping costs. This includes increased fuel-consumption, drydocking costs, remedial measures and revenue lost due to regular maintenance and downtime.

On hard surfaces in contact with raw seawater, the biofouling process can start in as little as 15 minutes. It starts with the settlement and build-up of slime and soon progresses to algae, weeds and then molluscs.

When marine fouling grows on the outside of a ship's hull, hydrodynamic drag increases which causes fuel consumption to rise. On the inside of a vessel, marine fouling will reduce cooling water flow and lead to major equipment failure if left unchecked.

On offshore structures like oil rigs and wind turbines, marine fouling will increase weight and hydrodynamic loading. Marine fouling will also account for around 30% of lifecycle corrosion in marine structures.

For decades, ultrasound has been used in the food, brewing and hydroponic farming industries to prevent algal blooms and to keep water-handling equipment clean and free from blockages.

Traditionally, poisons (biocides) have been used to kill organisms that settle on raw seawater surfaces like hulls and box cooler pipework.

Environmental legislation covering the use of poisonous metallic biocides in antifouling systems is tightening and marine-based industries are looking for more effective means of preventing unwanted marine growth on their vessels and inside their equipment

Sonihull antifouling systems use the power of ultrasound to protect the inside and outside of marine vessels and structures from unwanted marine growth.

Unlike conventional antifouling coating systems, Sonihull does not release poisonous biocides that kill marine organisms or use ablative coatings that leave microplastic pollution in their wake. Sonihull keeps surfaces clear using ultrasound-induced non-inertial cavitation, which disrupts the biofouling process and actively prevents barnacle and mussel attachment.

The Sonihull Ultrasonic Anti-fouling System is a Fit & Forget solution for hulls, marine structures, box coolers, sea chests, strainers ... wherever there is unwanted bio-fouling.

The Sonihull system prevents marine organisms from colonising solid surfaces that are exposed to raw seawater. Unlike biocidal coatings and impressed-current systems, Sonihull is low cost and low maintenance, with zero poisonous environmental legacy.

Fitting is very easy, there's no need to drydock and drain your box coolers, there's also no drilling, welding, or expensive copper anodes to replace regularly. When compared to impressed-current antifouling systems, the Sonihull system can reduce capital and MRO costs by up to 95%.

The Sonihull protection system utilizes the latest digital electronics and Ultrasonic transducer technology, by producing multiple bursts of ultra sonic energy simultaneously in a multiple range of frequencies.

This energy produces a pattern of alternating positive and negative pressure. The alternating pattern creates microscopic bubbles during periods of negative pressure and implodes them during periods of positive pressure in a phenomenon known as "cavitation."

The implosion creates a micro-jet action that not only provides the cleaning effect on the hulls surface below the water line, it also resonates and destroys single cell organisms such as algae. The removal of the initial link in the food chain inhibits the growth barnacles and other marine life that feed on the algae.

Although the concept of using ultrasonic for keeping your boat hull clean is a relatively new application, the concept of ultrasonic cleaning is not new, it has been around for over 30 years, used for a wide variety of applications, from cleaning of dental and medical equipment, fine jewelry, through to de-gunging drains and automotive parts to name but a few, also, in a subject closer to sailors hearts Ultrasonic's is also used for keeping pipes clean in many breweries and hostelries around the world.

Over the past decade, environmental issues have meant much tighter controls on industrial cleaning products especially chlorofluorocarbons, with "necessity being the mother of all inventions" industry needed to find an alternative solution, Ultrasonic cleaning was considered the most viable solution, by embracing the latest in digital electronics and transducer technology, the industry made a quantum leap forward over the last decade to fill the needs of industry.

"Cavitation" is the rapid formation and collapse of millions of tiny bubbles (or cavities) in a liquid. Cavitation is produced by the alternating high and low pressure waves generated by high frequency (ultrasonic) sound. During the low pressure phase, these bubbles grow from a microscopic size until, during the high pressure phase, they are compressed and implode.

Tests show that there is no danger to fish or marine mammals, (but if they can hear the ultra high frequencies and don't like it, they only have to swim a few more inches away from the hull to avoid the problem!)

A clean hull can save you 30% of fuel bill, It is common that fouling on the boat's hull will lead to increased resistance, which basically means you are going to burn more fuel for every knot you make. The outcome is compromised efficiency and a poorer mpg figure than with a clean hull, but by how much?

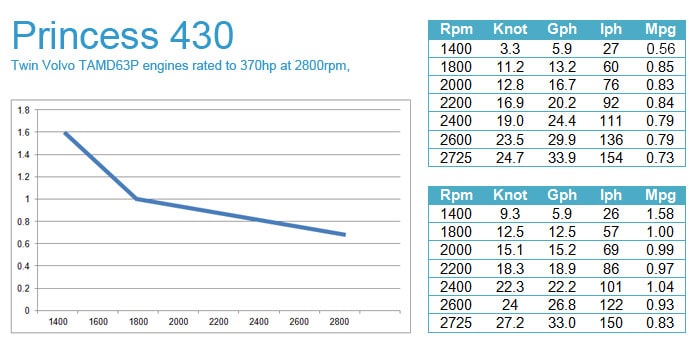

To answer this question a leading yacht journal undertook some comprehensive seatrials in a 10-year-old Princess 430 insatalled with twin Volvo TAMD63P engines rated to 370hp at 2800rpm, measuring its performance before and after its spring lift.

Painting the hull is not only for purpose of antifouling, it is also an important waterproofing barrier, protecting the gel coat from the effects (and immense cost) of osmosis. Therefore we would still recommend that the boat is protected under the water line. In some cases to maximize performance some yacht owners who have installed the sonihull system have opted to use a harder grade of antifouling paint, as apposed to the soft self polishing versions which have a higher drag factor through the water. So although there is still a need for painting below the water line, when using the sonihull system the need to do so will be greatly reduced.

Although we have received a few reports that this is the added benefit of installing an Ultrasonic system, and could be plausible due to the simple sell structure of Jellyfish, to-date there is no scientific data to prove this theory.

Yes, the same laws of physics apply but due to the surface area of the hull below the water line, several sonihull's would need to be installed to get the desired effect. Please also note that the transducers need to be bonded to the inside of the outer skin of the hull so please check that you can access this as some yachts have inner skins with a filled cavity that would hinder the acoustic transfer of the sound waves.

We recommend an epoxy glue such as araldite or equivalent. You will note that there is a gutter built in to the locking ring that is bonded to the hull, this is to prevent any access glue getting into the thread. It is also recommended to apply a little bit of petroleum jelly to the thread to protect it from any epoxy that gets squidged in to the thread.

No, sorry, but due to the low density of wood and the quantity of joints makes for poor acoustic transmission of high frequencies, so making the unit far less effective for this application.

A Sonihull is suitable for all single skin GPR, aluminium and Concrete hulls. Foam Core hulls have special installation requirements, please contact us for details.

Fill out the recommendation form below so that one of our experts can contact you.

* Required fields.