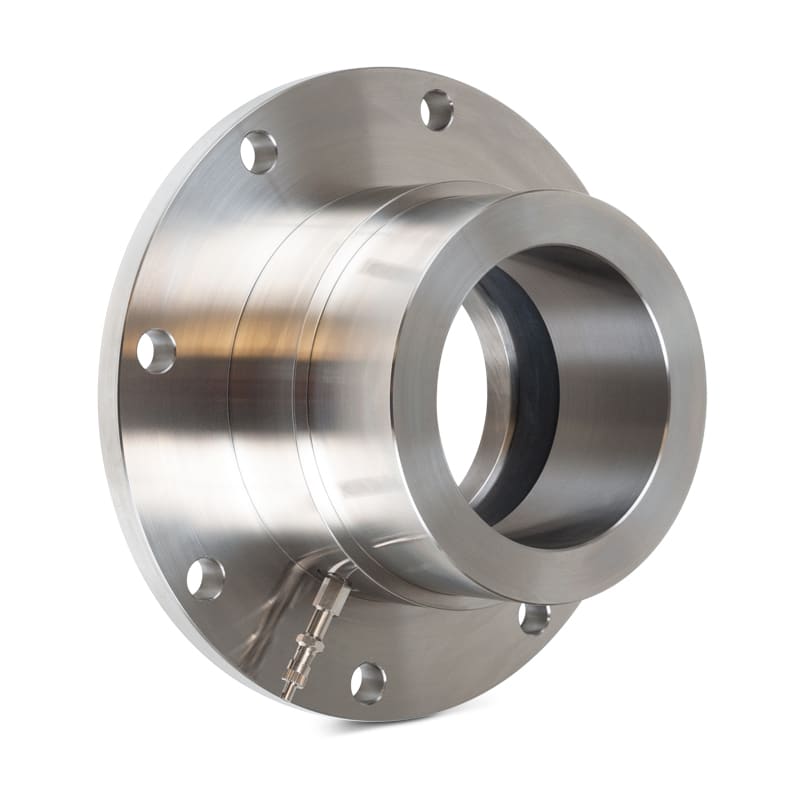

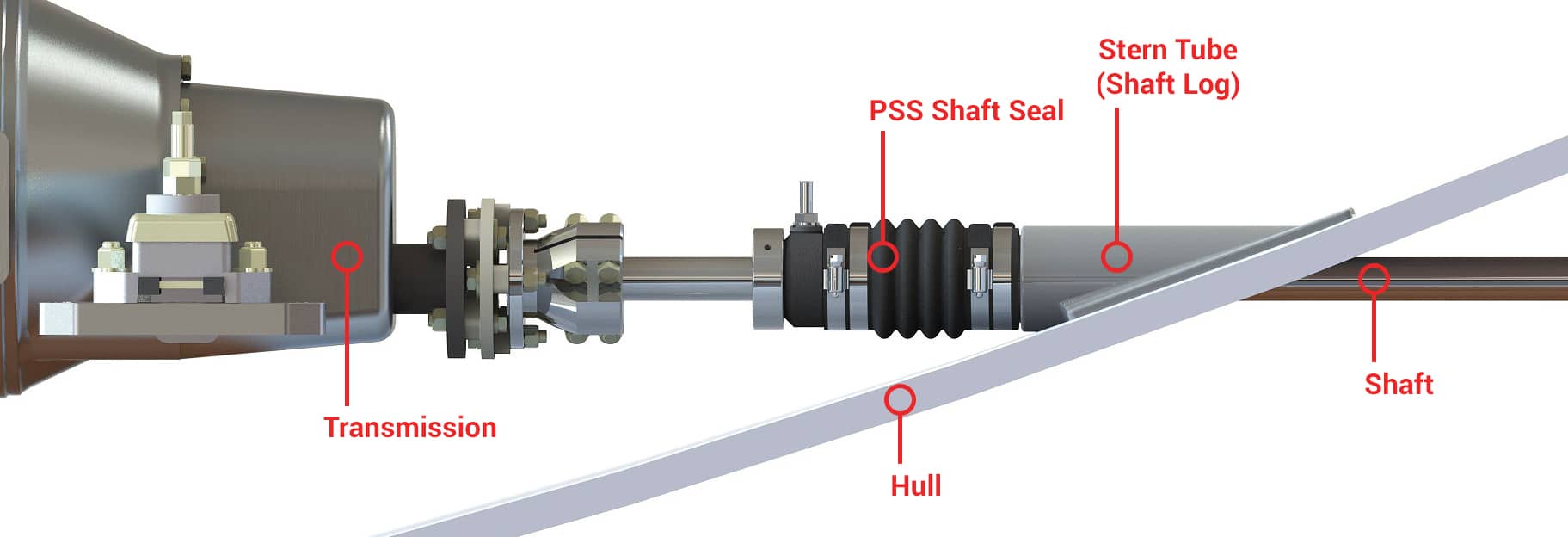

The PSS Shaft Seal is the #1 selling marine mechanical seal worldwide and is installed as standard equipment by many of the worlds most reputable boat builders and boatyards.

The PSS Shaft Seal is also recognized as the premiere retrofit (aftermarket) seal on the world market. Boat builders and boatyards recognize the advantages and value of installing the PSS as it eliminates the maintenance, constant adjustment, and cost associated with traditional packing type glands. Aside from these benefits, the PSS Shaft Seal helps to eliminate water in the bilge (100% watertight) and wear to the propeller shaft.

The PSS Shaft Seal can be easily retrofitted and is available for shafts ranging from 3/4” to 8” (20mm to 203mm).