GET A QUOTE

* These fields are required.

Shaft Seal Models

Weld on Stern Tube Model

This system features the standard PSS Type C Shaft Seal and is designed as a weld on system for both new construction and retrofit installations. Available in aluminum, steel or 316L, this mounting system ensures minimal installation time, integrates with many vessel configurations and eliminates the need for an additional adapter / bolt on system.

HOW DOES IT WORK ?

- 1

This clamp assembly maintains the PSS Type C preload / compression without the need for set screws.

- 2

Nitronic 50 SS rotor surfaced to 9 Ra finish.

- 3

Machined acetal hub with carbon stator insert, lapped to 4 HLB.

- 4

Water is fed into the PSS Shaft Seal for cooling/lubricating the seal faces on high speed vessels.

- 5

Stationary acetal/carbon stator clamped to the nitrile bellow, which is attached to the stern tube (shaft log)

- 6

T-Bolt Type Hose clamps secure the bellow to the stern tube and to the acetal/carbon stator to the bellow.

- 7

Stern Tube made from your choice of aluminum, steel or 316L stainless steel, will be directly welded onto the vessel.

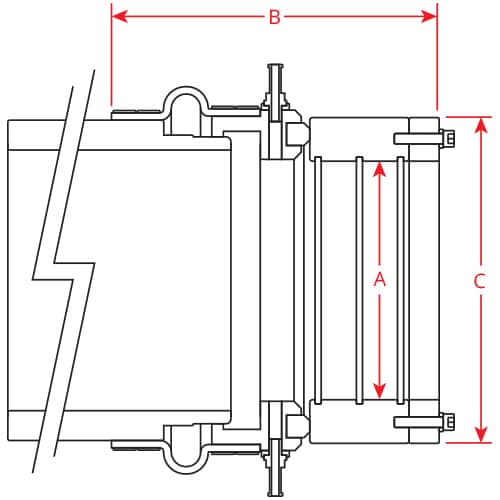

Dimensions

| Part # | Shaft Dia. (A) | Uncompressed Length (B) | Approx. Compression | Rotor Diameter (C) |

|---|---|---|---|---|

| 02-612-A | 6.500" | 10.982" | 0.500" | 10.938" |

| 02-700-A | 7.000" | 10.982" | 0.500" | 10.938" |

| 02-712-A | 7.500" | 10.982" | 0.500" | 10.938" |

| 02-800-A | 8.000" | 10.982" | 0.500" | 10.938" |

| 02-612-S | 6.500" | 10.982" | 0.500" | 10.938" |

| 02-700-S | 7.000" | 10.982" | 0.500" | 10.938" |

| 02-712-S | 7.500" | 10.982" | 0.500" | 10.938" |

| 02-800-S | 8.000" | 10.982" | 0.500" | 10.938" |

| 02-612-SS | 6.500" | 10.982" | 0.500" | 10.938" |

| 02-700-SS | 7.000" | 10.982" | 0.500" | 10.938" |

| 02-712-SS | 7.500" | 10.982" | 0.500" | 10.938" |

| 02-800-SS | 8.000" | 10.982" | 0.500" | 10.938" |

| Part # | Shaft Dia. (A) | Uncompressed Length (B) | Approx. Compression | Rotor Diameter (C) |

|---|---|---|---|---|

| 02-165M-A | 6.500" | 10.982" | 0.500" | 10.938" |

| 02-178M-A | 7.000" | 10.982" | 0.500" | 10.938" |

| 02-191M-A | 7.500" | 10.982" | 0.500" | 10.938" |

| 02-203M-A | 8.000" | 10.982" | 0.500" | 10.938" |

| 02-165M-S | 6.500" | 10.982" | 0.500" | 10.938" |

| 02-178M-S | 7.000" | 10.982" | 0.500" | 10.938" |

| 02-191M-S | 7.500" | 10.982" | 0.500" | 10.938" |

| 02-203M-S | 8.000" | 10.982" | 0.500" | 10.938" |

| 02-165M-SS | 6.500" | 10.982" | 0.500" | 10.938" |

| 02-178M-SS | 7.000" | 10.982" | 0.500" | 10.938" |

| 02-191M-SS | 7.500" | 10.982" | 0.500" | 10.938" |

| 02-203M-SS | 8.000" | 10.982" | 0.500" | 10.938" |

COMPONENTS

Rotor & Clamp Assembly

Acetal/Carbon STATOR

BELLOW

Hose Clamps

HOSE BARB

Stern Tube

Flange Mounted Model

Ideal for retrofit or new construction installations, this system includes the standard Type C Seal and is designed as a bolt on application. Available in aluminum, steel or 316L, this mounting system is machined to match your specific application/existing flange pattern and is offered "pre-drilled" to your bolt pattern, size and spacing or supplied "blank" for simplicity and drilling at the time of installation.

HOW DOES IT WORK ?

- 1

This clamp assembly maintains the PSS Type C preload / compression.

- 2

Nitronic 50 SS rotor surfaced to 9 Ra finish.

- 3

Machined acetal hub with carbon stator insert, lapped to 4 HCB.

- 4

This clamp assembly maintains the PSS Type C preload / compression.

- 5

T-Bolt style Hose clamps secure the bellow to the stern tube and to the acetal/carbon stator to the bellow.

- 6

Stationary acetal/carbon stator clamped to the silicone bellow, which is attached to the stern tube (shaft log)

- 7

Flange made from your choice of aluminum, steel or 316L stainless steel.

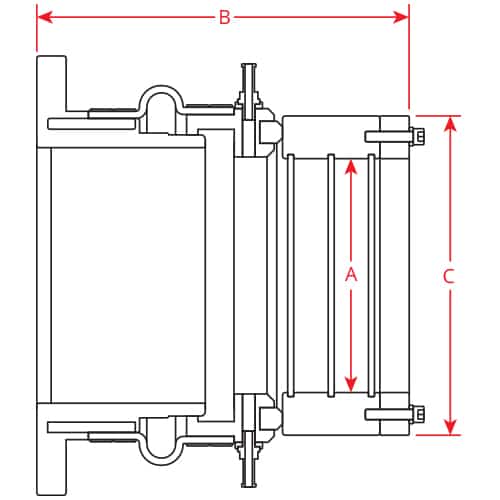

Dimensions

| Part # | Shaft Dia. (A) | Uncompressed Length (B) | Approx. Compression | Rotor Diameter (C) |

|---|---|---|---|---|

| 02-612-AF | 6.500" | 10.982" | 0.500" | 10.938" |

| 02-700-AF | 7.000" | 10.982" | 0.500" | 10.938" |

| 02-712-AF | 7.500" | 10.982" | 0.500" | 10.938" |

| 02-800-AF | 8.000" | 10.982" | 0.500" | 10.938" |

| 02-612-SF | 6.500" | 10.982" | 0.500" | 10.938" |

| 02-700-SF | 7.000" | 10.982" | 0.500" | 10.938" |

| 02-712-SF | 7.500" | 10.982" | 0.500" | 10.938" |

| 02-800-SF | 8.000" | 10.982" | 0.500" | 10.938" |

| 02-612-SSF | 6.500" | 10.982" | 0.500" | 10.938" |

| 02-700-SSF | 7.000" | 10.982" | 0.500" | 10.938" |

| 02-712-SSF | 7.500" | 10.982" | 0.500" | 10.938" |

| 02-800-SSF | 8.000" | 10.982" | 0.500" | 10.938" |

COMPONENTS

Rotor & Clamp Assembly

Acetal/Carbon STATOR

BELLOW

Hose Clamps

HOSE BARB

Flange

| Part # | Shaft Dia. (A) | Uncompressed Length (B) | Approx. Compression | Rotor Diameter (C) |

|---|---|---|---|---|

| 02-165M-AF | 6.500" | 10.982" | 0.500" | 10.938" |

| 02-178M-AF | 7.000" | 10.982" | 0.500" | 10.938" |

| 02-191M-AF | 7.500" | 10.982" | 0.500" | 10.938" |

| 02-203M-AF | 8.000" | 10.982" | 0.500" | 10.938" |

| 02-165M-SF | 6.500" | 10.982" | 0.500" | 10.938" |

| 02-178M-SF | 7.000" | 10.982" | 0.500" | 10.938" |

| 02-191M-SF | 7.500" | 10.982" | 0.500" | 10.938" |

| 02-203M-SF | 8.000" | 10.982" | 0.500" | 10.938" |

| 02-165M-SSF | 6.500" | 10.982" | 0.500" | 10.938" |

| 02-178M-SSF | 7.000" | 10.982" | 0.500" | 10.938" |

| 02-191M-SSF | 7.500" | 10.982" | 0.500" | 10.938" |

| 02-203M-SSF | 8.000" | 10.982" | 0.500" | 10.938" |

COMPONENTS

Rotor & Clamp Assembly

Acetal/Carbon STATOR

BELLOW

Hose Clamps

HOSE BARB

Flange

Flange & Bladder Mounted Model

Also ideal for retrofit or new construction installations, this sytem includes the standard PSS Type C Shaft Seal and is designed as a bolt on application. Available in aluminum, steel or 316L, this mounting system is machined to match your specific application, existing flange pattern and is offered "pre-drilled" to your bolt pattern, size, spacing or supplied "blank" for simplicity and drilling at the time of installation.

HOW DOES IT WORK ?

- 1

This clamp assembly maintains the PSS Type C preload / compression.

- 1

This clamp assembly maintains the PSS Type C preload / compression without the need for set screws.

- 1

Machined acetal hub with carbon stator insert, lapped to 4 HCB.

- 4

Water is fed into the PSS Shaft Seal for cooling/lubricating the seal faces on high speed vessels.

- 5

T-Bolt style Hose clamps secure the bellow to the stern tube and to the acetal/carbon stator to the bellow.

- 6

Stationary acetal/carbon stator clamped to the silicone bellow, which is attached to the stern tube (shaft log)

- 7

Flange made from your choice of aluminum, steel or 316L stainless steel. Inflatable bladder allows the operator to seal the stern tube, while the shaft is not rotating, in order to inspect or clean the seal. In addition, if the uncoupling of the shaft is needed, this operation can be done in the water as the shaft can be moved aft with bladder inflated with no water intrusion occurring.

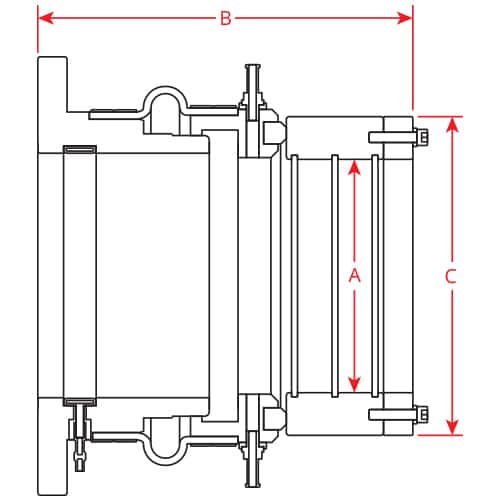

Dimensions

| Part # | Shaft Dia. (A) | Uncompressed Length (B) | Approx. Compression | Rotor Diameter (C) |

|---|---|---|---|---|

| 02-612-ABF | 6.500" | 10.982" | 0.500" | 10.938" |

| 02-700-ABF | 7.000" | 10.982" | 0.500" | 10.938" |

| 02-712-ABF | 7.500" | 10.982" | 0.500" | 10.938" |

| 02-800-ABF | 8.000" | 10.982" | 0.500" | 10.938" |

| 02-612-SBF | 6.500" | 10.982" | 0.500" | 10.938" |

| 02-700-SBF | 7.000" | 10.982" | 0.500" | 10.938" |

| 02-712-SBF | 7.500" | 10.982" | 0.500" | 10.938" |

| 02-800-SBF | 8.000" | 10.982" | 0.500" | 10.938" |

| 02-612-SSBF | 6.500" | 10.982" | 0.500" | 10.938" |

| 02-700-SSBF | 7.000" | 10.982" | 0.500" | 10.938" |

| 02-712-SSBF | 7.500" | 10.982" | 0.500" | 10.938" |

| 02-800-SSBF | 8.000" | 10.982" | 0.500" | 10.938" |

Components

Rotor & Clamp Assembly

Acetal/Carbon STATOR

BELLOW

Hose Clamps

HOSE BARB

Flange & Bladder

| Part # | Shaft Dia. (A) | Uncompressed Length (B) | Approx. Compression | Rotor Diameter (C) |

|---|---|---|---|---|

| 02-165M-ABF | 6.500" | 10.982" | 0.500" | 10.938" |

| 02-178M-ABF | 7.000" | 10.982" | 0.500" | 10.938" |

| 02-191M-ABF | 7.500" | 10.982" | 0.500" | 10.938" |

| 02-203M-ABF | 8.000" | 10.982" | 0.500" | 10.938" |

| 02-165M-SBF | 6.500" | 10.982" | 0.500" | 10.938" |

| 02-178M-SBF | 7.000" | 10.982" | 0.500" | 10.938" |

| 02-191M-SBF | 7.500" | 10.982" | 0.500" | 10.938" |

| 02-203M-SBF | 8.000" | 10.982" | 0.500" | 10.938" |

| 02-165M-SSBF | 6.500" | 10.982" | 0.500" | 10.938" |

| 02-178M-SSBF | 7.000" | 10.982" | 0.500" | 10.938" |

| 02-191M-SSBF | 7.500" | 10.982" | 0.500" | 10.938" |

| 02-203M-SSBF | 8.000" | 10.982" | 0.500" | 10.938" |

COMPONENTS

Rotor & Clamp Assembly

Acetal/Carbon STATOR

BELLOW

Hose Clamps

HOSE BARB

Flange & Bladder

CERTIFICATES

RINA

BUREAU VERITAS