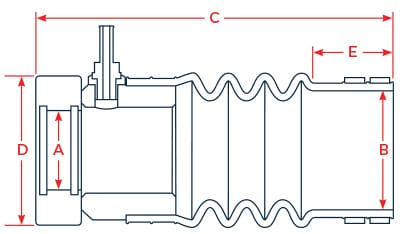

For 20 to 95mm (3/4" to 3-3/4") - (Dimensions)

The PSS PRO Shaft Seal is a mechanical face seal utilizing our proven stainless steel and carbon sealing components, but adds a reinforced silicone bellow, a secondary shaft retention collar, 316 Stainless Steel hose clamps (rolled edges & non-perforated) and an optional Nitronic 50 rotor upgrade (for highly corrosive environments). Designed specifically for applications that will require increased durability and resistance to harsh, corrosive, high pressure and otherwise demanding environments. The PSS PRO Shaft Seal is a specialized mechanical seal that is suitable for a variety of applications, with unmatched performance.

As with PSS Type A & B Seals, The PRO Shaft Seal is a mechanical face seal. The sealing surface is created between the flat surfaces of the rotating stainless-steel rotor and the stationary carbon flange. The stationary carbon flange is attached to a heavy-duty silicone bellow which is attached to the vessel’s stern tube (shaft log), with 316SS hose clamps. The stainless-steel rotor is fitted on the shaft in front of the carbon flange and is used to compress the bellow, the rotor is then secured to the shaft with set-screws and the shaft retention collar is installed. This compression (pre-load) maintains constant contact between the two mating faces of the stainless-steel rotor and carbon flange, allowing the PSS to compensate for the variable axial movement due to propeller thrust. The carbon flange is over-bored to the shaft diameter allowing it to “float” around the shaft and thus compensate for most misalignment and vibration from the drive-line. The stainless-steel rotor is sealed to the shaft by two O-rings that are recessed into the bore of the rotor. These O-rings rotate with the shaft and the stainless-steel rotor, and therefore do not experience wear during operation.

Temperature Limits: -13°F to 425°F (-25°C to 220°C)

Pressure Limits: 40 PSI (2.75 BAR)

Shaft RPM Limits: 10,000 RPM

Carbon Graphite: Lapped to 4 HLB (0.000044" tolerance)

316SS / Nitronic 50: Faced to 9-12 Ra

Bellows Material: Molded formed silicone / fabric

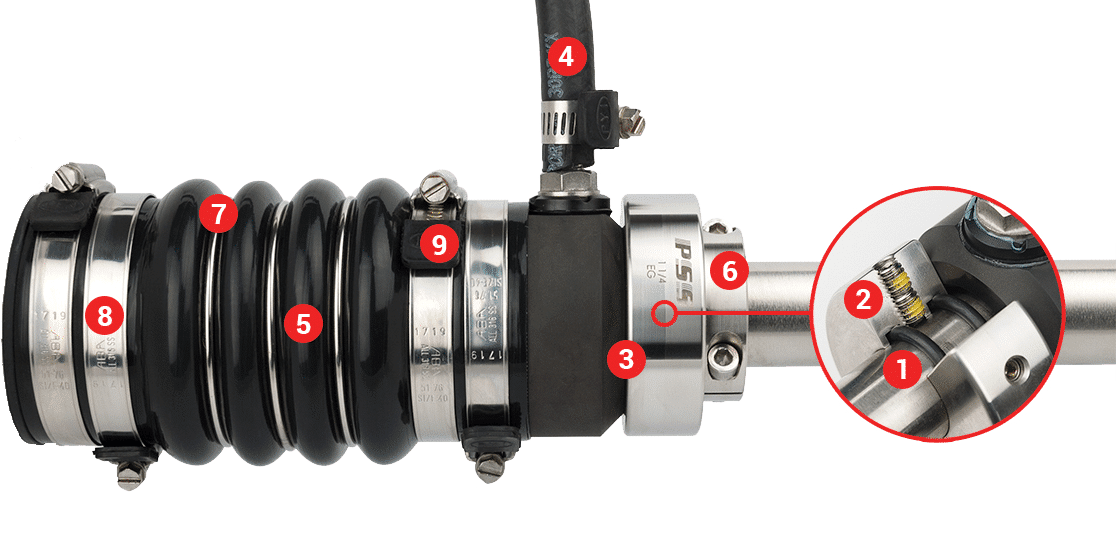

HOW DOES IT WORK ?

1 Two nitrile o-rings seal the stainless steel rotor to the shaft and will not experience wear.

2 A primary set screw and a backup set screw (2 sets) are used to secure the stainless steel rotor to the shaft.

3 A seal is created between the two mating faces of the carbon stator and the stainless steel rotor.

4 Raw water is fed to the PSS Shaft Seal for cooling / lubricating the seal faces on high speed vessels.

5 The stationary carbon stator is attached to the bellow, which is secured to the stern tube (shaft log).

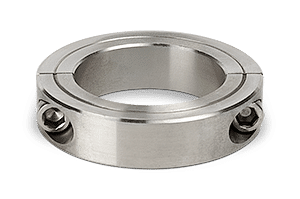

6 The Shaft Retention Collar is attached to the shaft and helps retain the propeller or rudder shaft in your vessel in the event of catastrophic failure of the coupling or if the shaft comes free from the coupling.

7 Stainless steel rings are fit to the bellow for increased strength, support and durability. External rings come standard on sizes 2-1/4" (60mm) to 3-3/4" (95mm) and optional for smaller sizes.

8 316SS hose clamps with rolled edges and non-perforated band.

9 Hose clamp tail protection, Clamp Jackets.

COMPONENTS

SHAFT RETENTION COLLAR

CARBON STATOR

BELLOW RINGS

ROTOR

HOSE BARB

BELLOW

DIMENSIONS

| Part # | Shaft Dia. (A) | Stern Tube Dia. (B) | Uncompressed Length (C) | Approx. Compressed Length | Rotor Diameter (D) | Stern Cuff Length (E) |

|---|---|---|---|---|---|---|

| 03-034-114 | 3/4" | 1-1/4" to 1-3/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-034-112 | 3/4" | 1-1/2" to 1-5/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-034-134 | 3/4" | 1-3/4" to 1-7/8" | 7.675" | 6.925" | 0.875" | 1.625" |

| 03-034-200 | 3/4" | 2" to 2-1/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-034-214 | 3/4" | 2-1/4" to 2-3/8" | 7.675" | 6.925" | 0.875" | 1.625" |

| 03-034-212 | 3/4" | 2-1/2" to 2-5/8" | 8.75" | 8" | 0.875" | 1.625" |

| 03-078-114 | 7/8" | 1-1/4" to 1-3/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-078-112 | 7/8" | 1-1/2" to 1-5/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-078-134 | 7/8" | 1-3/4" to 1-7/8" | 7.675" | 6.925" | 0.875" | 1.625" |

| 03-078-200 | 7/8" | 2" to 2-1/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-078-214 | 7/8" | 2-1/4" to 2-3/8" | 7.675" | 6.925" | 0.875" | 1.625" |

| 03-078-212 | 7/8" | 2-1/2" to 2-5/8" | 8.75" | 8" | 0.875" | 1.625" |

| 03-100-114 | 1" | 1-1/4" to 1-3/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-100-112 | 1" | 1-1/2" to 1-5/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-100-134 | 1" | 1-3/4" to 1-7/8" | 7.675" | 6.925" | 0.875" | 1.625" |

| 03-100-200 | 1" | 2" to 2-1/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-100-214 | 1" | 2-1/4" to 2-3/8" | 7.675" | 6.925" | 0.875" | 1.625" |

| 03-100-212 | 1" | 2-1/2" to 2-5/8" | 8.75" | 8" | 0.875" | 1.625" |

| 03-118-114 | 1-1/8" | 1-1/4" to 2-3/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-118-112 | 1-1/8" | 1-1/2" to 2-5/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-118-134 | 1-1/8" | 1-3/4" to 2-7/8" | 7.675" | 6.925" | 0.875" | 1.625" |

| 03-118-200 | 1-1/8" | 2" to 2-1/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-118-214 | 1-1/8" | 2-1/4" to 2-3/8" | 7.675" | 6.925" | 0.875" | 1.625" |

| 03-118-212 | 1-1/8" | 2-1/2" to 2-5/8" | 8.75" | 8" | 0.875" | 1.625" |

| 03-114-134 | 1-1/4" | 1-3/4" to 1-7/8" | 8.930" | 8.180" | 2.875" | 1.3" |

| 03-114-200 | 1-1/4" | 2" to 2-1/8" | 8.805" | 8.055" | 2.875" | 1.3" |

| 03-114-214 | 1-1/4" | 2-1/4" to 2-3/8" | 8.930" | 8.180" | 2.875" | 1.3" |

| 03-114-212 | 1-1/4" | 2-1/2" to 2-5/8" | 8.805" | 8.055" | 2.875" | 1.3" |

| 03-114-234 | 1-1/4" | 2-3/4" to 2-7/8" | 10.305" | 9.555" | 2.875" | 1.3" |

| 03-114-300 | 1-1/4" | 3" to 3-1/8" | 10.305" | 9.555" | 2.875" | 1.3" |

| 03-114-314 | 1-1/4" | 3-1/4" to 3-3/8" | 10.493" | 9.743" | 2.875" | 1.3" |

| 03-114-312 | 1-1/4" | 3-1/2" to 3-5/8" | 10.305" | 9.555" | 2.875" | 1.3" |

| 03-138-134 | 1-3/8" | 1-3/4" to 1-7/8" | 8.430" | 7.680" | 2.875" | 1.3" |

| 03-138-200 | 1-3/8" | 2" to 2-1/8" | 8.868" | 8.118" | 2.875" | 1.5" |

| 03-138-214 | 1-3/8" | 2-1/4" to 2-3/8" | 8.993" | 8.243" | 2.875" | 1.3" |

| 03-138-212 | 1-3/8" | 2-1/2" to 2-5/8" | 8.868" | 8.118" | 2.875" | 1.3" |

| 03-138-234 | 1-3/8" | 2-3/4" to 2-7/8" | 10.368" | 9.618" | 2.875" | 1.3" |

| 03-138-300 | 1-3/8" | 3" to 3-1/8" | 10.368" | 9.618" | 2.875" | 1.3" |

| 03-138-312 | 1-3/8" | 3-1/2" to 3-5/8" | 10.368" | 9.618" | 2.875" | 1.3" |

| 03-112-200 | 1-1/2" | 2" to 2-1/8" | 8.968" | 7.968" | 3.75" | 1.3" |

| 03-112-214 | 1-1/2" | 2-1/4" to 2-3/8" | 8.968" | 7.968" | 3.75" | 1.3" |

| 03-112-212 | 1-1/2" | 2-1/2" to 2-5/8" | 8.843" | 7.843" | 3.75" | 1.3" |

| 03-112-234 | 1-1/2" | 2-3/4" to 2-7/8" | 9.331" | 8.331" | 3.75" | 1.3" |

| 03-112-300 | 1-1/2" | 3" to 3-1/8" | 9.143" | 8.143" | 3.75" | 1.3" |

| 03-112-314 | 1-1/2" | 3-1/4" to 3-3/8" | 9.331" | 8.331" | 3.75" | 1.3" |

| 03-112-312 | 1-1/2" | 3-1/2" to 3-5/8" | 9.143" | 8.143" | 3.75" | 1.3" |

| 03-112-334 | 1-1/2" | 3-3/4" to 3-7/8" | 9.268" | 8.268" | 3.75" | 1.3" |

| 03-112-400 | 1-1/2" | 4" to 4-1/8" | 9.268" | 8.268" | 3.75" | 1.3" |

| 03-1916-212 | 1-9/16" | 2" to 2-1/1" | 8.843" | 7.843" | 3.75" | 1.3" |

| 03-1916-300 | 1-9/16" | 2" to 2-1/1" | 9.143" | 8.143" | 3.75" | 1.3" |

| 03-134-214 | 1-3/4" | 2-1/4" to 2-3/8" | 9.093" | 8.093" | 3.75" | 1.3" |

| 03-134-212 | 1-3/4" | 2-1/2" to 2-5/8" | 8.968" | 7.968" | 3.75" | 1.3" |

| 03-134-234 | 1-3/4" | 2-3/4" to 2-7/8" | 9.456" | 8.456" | 3.75" | 1.3" |

| 03-134-300 | 1-3/4" | 3" to 3-1/8" | 9.268" | 8.268" | 3.75" | 1.3" |

| 03-134-314 | 1-3/4" | 3-1/4" to 3-3/8" | 9.456" | 8.456" | 3.75" | 1.3" |

| 03-134-312 | 1-3/4" | 3-1/2" to 3-5/8" | 9.268" | 8.268" | 3.75" | 1.3" |

| 03-134-334 | 1-3/4" | 3-3/4" to 3-7/8" | 9.393" | 8.393" | 3.75" | 1.3" |

| 03-134-400 | 1-3/4" | 4" to 4-1/8" | 9.393" | 8.393" | 3.75" | 1.3" |

| 03-200-212 | 2" | 2-1/2" to 2-5/8" | 8.968" | 7.968" | 3.75" | 1.3" |

| 03-200-234 | 2" | 2-3/4" to 2-7/8" | 9.456" | 8.456" | 3.75" | 1.3" |

| 03-200-300 | 2" | 3" to 3-1/8" | 9.268" | 8.268" | 3.75" | 1.3" |

| 03-200-314 | 2" | 3-1/4" to 3-3/8" | 9.456" | 8.456" | 3.75" | 1.3" |

| 03-200-312 | 2" | 3-1/2" to 3-5/8" | 9.268" | 8.268" | 3.75" | 1.3" |

| 03-200-334 | 2" | 3-3/4" to 3-7/8" | 9.393" | 8.393" | 3.75" | 1.3" |

| 03-200-400 | 2" | 4" to 4-1/8" | 9.393" | 8.393" | 3.75" | 1.3" |

| 03-214-314 | 2-1/4" | 3-1/4" to 3-3/8" | 9.863" | 8.863" | 4.2" | 1.3" |

| 03-214-312 | 2-1/4" | 3-1/2" to 3-5/8" | 9.675" | 8.675" | 4.2" | 1.3" |

| 03-214-334 | 2-1/4" | 3-3/4" to 3-7/8" | 9.675" | 8.675" | 4.2" | 1.3" |

| 03-214-400 | 2-1/4" | 4" to 4-1/8" | 9.675" | 8.675" | 4.2" | 1.3" |

| 03-214-414 | 2-1/4" | 4-1/4" to 4-3/8" | 9.800" | 8.800" | 4.2" | 1.3" |

| 03-214-412 | 2-1/4" | 4-1/2" to 4-5/8" | 9.800" | 8.800" | 4.2" | 1.3" |

| 03-214-434 | 2-1/4" | 4-3/4" to 4-7/8" | 10.670" | 9.670" | 4.2" | 1.3" |

| 03-214-500 | 2-1/4" | 5" to 5-1/8" | 10.670" | 9.670 | 4.2" | 1.3" |

| 03-212-314 | 2-1/2" | 3-1/4" to 3-3/8" | 9.800" | 8.800" | 4.2" | 1.3" |

| 03-212-312 | 2-1/2" | 3-1/2" to 3-5/8" | 9.800" | 8.800" | 4.2" | 1.3" |

| 03-212-334 | 2-1/2" | 3-3/4" to 3-7/8" | 9.800" | 8.800" | 4.2" | 1.3" |

| 03-212-400 | 2-1/2" | 4" to 4-1/8" | 9.800" | 8.800" | 4.2" | 1.3" |

| 03-212-414 | 2-1/2" | 4-1/4" to 4-3/8" | 9.925" | 8.925" | 4.2" | 1.3" |

| 03-212-412 | 2-1/2" | 4-1/2" to 4-5/8" | 9.925" | 8.925" | 4.2" | 1.3" |

| 03-212-434 | 2-1/2" | 4-3/4" to 4-7/8" | 10.795" | 9.795" | 4.2" | 1.3" |

| 03-212-500 | 2-1/2" | 5" to 5-1/8" | 10.795" | 9.795" | 4.2" | 1.3" |

| 03-234-400 | 2-3/4" | 4" to 4-1/8" | 9.988" | 8.988" | 5" | 1.3" |

| 03-234-414 | 2-3/4" | 4-1/4" to 4-3/8" | 9.988" | 8.988" | 5" | 1.3" |

| 03-234-412 | 2-3/4" | 4-1/2" to 4-5/8" | 9.800" | 8.800" | 5" | 1.3" |

| 03-234-434 | 2-3/4" | 4-3/4" to 4-7/8" | 10.858" | 9.858" | 5" | 2.5" |

| 03-234-500 | 2-3/4" | 5" to 5-1/8" | 10.670" | 9.670" | 5" | 2.5" |

| 03-234-514 | 2-3/4" | 5-1/4" to 5-3/8" | 9.925" | 8.925" | 5" | 1.3" |

| 03-234-512 | 2-3/4" | 5-1/2" to 5-5/8" | 10.795" | 9.795" | 5" | 2.5" |

| 03-300-400 | 3" | 4" to 4-1/8" | 9.988" | 8.988" | 5" | 1.3" |

| 03-300-414 | 3" | 4-1/4" to 4-3/8" | 9.988" | 8.988" | 5" | 1.3" |

| 03-300-412 | 3" | 4-1/2" to 4-5/8" | 9.800" | 8.800" | 5" | 1.3" |

| 03-300-434 | 3" | 4-3/4" to 4-7/8" | 10.858" | 9.858" | 5" | 2.5" |

| 03-300-500 | 3" | 5" to 5-1/8" | 10.670" | 9.670" | 5" | 2.5" |

| 03-300-514 | 3" | 5-1/4" to 5-3/8" | 9.925" | 8.925" | 5.25" | 1.3" |

| 03-300-512 | 3" | 5-1/2" to 5-5/8" | 10.983" | 9.983" | 5" | 2.5" |

| 03-300-534 | 3" | 5-3/4" to 5-7/8" | 10.795" | 9.795" | 5" | 2.5" |

| 03-300-600 | 3" | 6" to 6-1/8" | 10.795" | 9.795" | 5" | 2.5" |

| 03-314-412 | 3-1/4" | 4-1/2" to 4-5/8" | 10.538" | 9.538" | 6" | 1.3" |

| 03-314-434 | 3-1/4" | 4-3/4" to 4-7/8" | 10.538" | 9.538" | 6" | 1.3" |

| 03-314-500 | 3-1/4" | 5" to 5-1/8" | 10.538" | 9.538" | 6" | 1.3" |

| 03-314-514 | 3-1/4" | 5-1/4" to 5-3/8" | 10.350" | 9.350" | 6" | 1.3" |

| 03-314-512 | 3-1/4" | 5-1/2" to 5-5/8" | 11.408" | 10.408" | 6" | 2.5" |

| 03-314-534 | 3-1/4" | 5-3/4" to 5-7/8" | 11.408" | 10.408" | 6" | 2.5" |

| 03-314-600 | 3-1/4" | 6" to 6-1/8" | 11.220" | 10.220" | 6" | 2.5" |

| 03-312-412 | 3-1/2" | 4-1/2" to 4-5/8" | 10.538" | 9.538" | 6" | 1.3" |

| 03-312-434 | 3-1/2" | 4-3/4" to 4-7/8" | 10.538" | 9.538" | 6" | 1.3" |

| 03-312-500 | 3-1/2" | 5" to 5-1/8" | 10.538" | 9.538" | 6" | 1.3" |

| 03-312-514 | 3-1/2" | 5-1/4" to 5-3/8" | 10.350" | 9.350" | 6" | 1.3" |

| 03-312-512 | 3-1/2" | 5-1/2" to 5-5/8" | 11.408" | 10.408" | 6" | 2.5" |

| 03-312-534 | 3-1/2" | 5-3/4" to 5-7/8" | 11.408" | 10.408" | 6" | 2.5" |

| 03-312-600 | 3-1/2" | 6" to 6-1/8" | 11.220" | 10.220" | 6" | 2.5" |

| 03-312-612 | 3-1/2" | 6-1/2" to 6-5/8" | 12.300" | 11.300" | 6" | 1.3" |

| 03-358-600 | 3-5/8" | 6" to 6-1/8" | 11.220" | 10.220" | 6" | 2.5" |

| 03-358-612 | 3-5/8" | 6-1/2" to 6-5/8" | 12.300" | 11.300" | 6" | 1.3" |

| 03-334-412 | 3-3/4" | 4-1/2" to 4-5/8" | 10.538" | 9.538" | 6" | 1.3" |

| 03-334-434 | 3-3/4" | 4-3/4" to 4-7/8" | 10.538" | 9.538" | 6" | 1.3" |

| 03-334-500 | 3-3/4" | 5" to 5-1/8" | 10.538" | 9.538" | 6" | 1.3" |

| 03-334-514 | 3-3/4" | 5-1/4" to 5-3/8" | 10.350" | 9.350" | 6" | 1.3" |

| 03-334-512 | 3-3/4" | 5-1/2" to 5-5/8" | 11.408" | 10.408" | 6" | 2.5" |

| 03-334-534 | 3-3/4" | 5-3/4" to 5-7/8" | 11.408" | 10.408" | 6" | 2.5" |

| 03-334-600 | 3-3/4" | 6" to 6-1/8" | 11.220" | 10.220" | 6" | 2.5" |

| Part # | Shaft Dia. (A) | Stern Tube Dia. (B) | Approx. Length (C) | Approx. Compressed Length | Rotor Diameter (D) | Stern Cuff Length (E) |

|---|---|---|---|---|---|---|

| 03-20M-114 | 20mm | 1-1/4" to 1-3/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-20M-112 | 20mm | 1-1/2" to 1-5/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-20M-134 | 20mm | 1-3/4" to 1-7/8" | 7.675" | 6.925" | 0.875" | 1.625" |

| 03-20M-200 | 20mm | 2" to 2-1/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-20M-214 | 20mm | 2-1/4" to 2-3/8" | 7.675" | 6.925" | 0.875" | 1.625" |

| 03-20M-212 | 20mm | 2-1/2" to 2-5/8" | 8.75" | 8" | 0.875" | 1.625" |

| 03-22M-114 | 22mm | 1-1/4" to 2-3/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-22M-112 | 22mm | 1-1/2" to 1-5/8" | 8.75" | 8" | 0.875" | 1.625" |

| 03-22M-134 | 22mm | 1-3/4" to 1-7/8" | 7.675" | 6.925" | 0.875" | 1.625" |

| 03-22M-200 | 22mm | 2" to 2-1/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-22M-214 | 22mm | 2-1/4" to 2-3/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-22M-212 | 22mm | 2-1/2" to 2-5/8" | 8.75" | 8" | 0.875" | 1.625" |

| 03-25M-114 | 25mm | 1-1/4" to 1-3/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-25M-112 | 25mm | 1-1/2" to 1-5/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-25M-134 | 25mm | 1-3/4" to 1-7/8" | 7.675" | 6.925" | 0.875" | 1.625" |

| 03-25M-200 | 25mm | 2" to 2-1/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-25M-214 | 25mm | 2-1/4" to 2-3/8" | 7.675" | 6.925" | 0.875" | 1.625" |

| 03-25M-212 | 25mm | 2-1/2" to 2-5/8" | 8.75" | 8" | 0.875" | 1.625" |

| 03-28M-114 | 25mm | 1-1/4" to 1-3/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-28M-112 | 25mm | 1-1/2" to 1-5/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-28M-134 | 25mm | 1-3/4" to 1-7/8" | 7.675" | 6.925" | 0.875" | 1.625" |

| 03-28M-200 | 25mm | 2" to 2-1/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-28M-214 | 25mm | 2-1/4" to 2-3/8" | 7.675" | 6.925" | 0.875" | 1.625" |

| 03-28M-212 | 25mm | 2-1/2" to 2-5/8" | 8.75" | 8" | 0.875" | 1.625" |

| 03-30M-114 | 30mm | 1-1/4" to 1-3/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-30M-112 | 30mm | 1-1/2" to 1-5/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-30M-134 | 30mm | 1-3/4" to 1-7/8" | 7.675" | 6.925" | 0.875" | 1.625" |

| 03-30M-200 | 30mm | 2" to 2-1/8" | 7.8" | 7.05" | 0.875" | 1.625" |

| 03-30M-214 | 30mm | 2-1/4" to 2-3/8" | 7.675" | 6.925" | 0.875" | 1.625" |

| 03-30M-212 | 30mm | 2-1/2" to 2-5/8" | 8.75" | 8" | 0.875" | 1.625" |

| 03-32M-134 | 32mm | 1-3/4" to 1-7/8" | 8.930" | 8.180" | 2.875" | 1.3" |

| 03-32M-200 | 32mm | 2" to 2-1/8" | 8.805" | 8.055" | 2.875" | 1.3" |

| 03-32M-214 | 32mm | 2-1/4" to 2-3/8" | 8.930" | 8.180" | 2.875" | 1.3" |

| 03-32M-212 | 32mm | 2-1/2" to 2-5/8" | 8.805" | 8.055" | 2.875" | 1.3" |

| 03-32M-234 | 32mm | 2-3/4" to 2-7/8" | 10.305" | 9.555" | 2.875" | 1.3" |

| 03-32M-300 | 32mm | 3" to 3-1/8" | 10.305" | 9.555" | 2.875" | 1.3" |

| 03-35M-134 | 35mm | 1-3/4" to 1-7/8" | 8.993" | 8.243" | 2.875" | 1.3" |

| 03-35M-200 | 35mm | 2" to 2-1/8" | 8.868" | 8.118" | 2.875" | 1.3" |

| 03-35M-214 | 35mm | 2-1/4" to 2-3/8" | 8.993" | 8.243" | 2.875" | 1.3" |

| 03-35M-212 | 35mm | 2-1/2" to 2-5/8" | 8.868" | 8.118" | 2.875" | 1.3" |

| 03-35M-234 | 35mm | 2-3/4" to 2-7/8" | 10.368" | 9.618" | 2.875" | 1.3" |

| 03-35M-300 | 35mm | 3" to 3-1/8" | 10.368" | 9.618" | 2.875" | 1.3" |

| 03-38M-200 | 38mm | 2" to 2-1/8" | 8.968" | 7.968" | 3.75" | 1.3" |

| 03-38M-214 | 38mm | 2-1/4" to 2-1/8" | 8.968" | 7.968" | 3.75" | 1.3" |

| 03-38M-212 | 38mm | 2-1/2" to 2-5/8" | 8.843" | 7.843" | 3.75" | 1.3" |

| 03-38M-234 | 38mm | 2-3/4" to 2-7/8" | 9.331" | 8.331" | 3.75" | 1.3" |

| 03-38M-300 | 38mm | 3" to 3-1/8" | 9.143" | 8.143" | 3.75" | 1.3" |

| 03-38M-314 | 38mm | 3-1/4" to 3-3/8" | 9.331" | 8.331" | 3.75" | 1.3" |

| 03-38M-312 | 38mm | 3-1/2" to 3-5/8" | 9.143" | 8.143" | 3.75" | 1.3" |

| 03-38M-334 | 38mm | 3-3/4" to 3-7/8" | 9.268" | 8.268" | 3.75" | 1.3" |

| 03-38M-400 | 38mm | 4" to 4-1/8" | 9.268" | 8.268" | 3.75" | 1.3" |

| 03-40M-200 | 40mm | 2" to 2-1/8" | 8.968" | 7.968" | 3.75" | 1.3" |

| 03-40M-214 | 40mm | 2-1/4" to 2-3/8" | 8.968" | 7.968" | 3.75" | 1.3" |

| 03-40M-212 | 40mm | 2-1/2" to 2-5/8" | 8.843" | 7.843" | 3.75" | 1.3" |

| 03-40M-234 | 40mm | 2-3/4" to 2-7/8" | 9.331" | 8.331" | 3.75" | 1.3" |

| 03-40M-300 | 40mm | 3" to 3-1/8" | 9.143" | 8.143" | 3.75" | 1.3" |

| 03-40M-314 | 40mm | 3-1/4" to 3-3/8" | 9.331" | 8.331" | 3.75" | 1.3" |

| 03-40M-312 | 40mm | 3-1/2" to 3-5/8" | 9.143" | 8.143" | 3.75" | 1.3" |

| 03-40M-334 | 40mm | 3-3/4" to 3-7/8" | 9.268" | 8.268" | 3.75" | 1.3" |

| 03-40M-400 | 40mm | 4" to 4-1/8" | 9.268" | 8.268" | 3.75" | 1.3" |

| 03-45M-214 | 45mm | 2-1/4" to 2-3/8" | 9.093" | 8.093" | 3.75" | 1.3" |

| 03-45M-212 | 45mm | 2-1/2" to 2-5/8" | 8.968" | 7.968" | 3.75" | 1.3" |

| 03-45M-234 | 45mm | 2-3/4" to 2-7/8" | 9.456" | 8.456" | 3.75" | 1.3" |

| 03-45M-300 | 45mm | 3" to 3-1/8" | 9.268" | 8.268" | 3.75" | 1.3" |

| 03-45M-314 | 45mm | 3-1/4" to 3-3/8" | 9.456" | 8.456" | 3.75" | 1.3" |

| 03-45M-312 | 45mm | 3-1/2" to 3-5/8" | 9.268" | 8.268" | 3.75" | 1.3" |

| 03-45M-334 | 45mm | 3-3/4" to 3-7/8" | 9.393" | 8.393" | 3.75" | 1.3" |

| 03-45M-400 | 45mm | 4" to 4-1/8" | 9.393" | 8.393" | 3.75" | 1.3" |

| 03-50M-212 | 50mm | 4" to 4-1/8" | 8.968" | 7.968" | 3.75" | 1.3" |

| 03-50M-234 | 50mm | 2-3/4" to 2-7/8" | 9.456" | 8.456" | 3.75" | 1.3" |

| 03-50M-300 | 50mm | 3" to 3-1/8" | 9.268" | 8.268" | 3.75" | 1.3" |

| 03-50M-314 | 50mm | 3-1/4" to 3-3/8" | 9.456" | 8.456" | 3.75" | 1.3" |

| 03-50M-312 | 50mm | 3-1/2" to 3-5/8" | 9.268" | 8.268" | 3.75" | 1.3" |

| 03-50M-334 | 50mm | 3-3/4" to 3-7/8" | 9.393" | 8.393" | 3.75" | 1.3" |

| 03-50M-400 | 50mm | 4" to 4-1/8" | 9.393" | 8.393" | 3.75" | 1.3" |

| 03-55M-212 | 55mm | 2-1/2" to 2-5/8" | 8.968" | 7.968" | 3.75" | 1.3" |

| 03-55M-234 | 55mm | 2-3/4" to 2-7/8" | 9.456" | 8.456" | 3.75" | 1.3" |

| 03-55M-300 | 55mm | 3" to 3-1/8" | 9.268" | 8.268" | 3.75" | 1.3" |

| 03-55M-314 | 55mm | 3-1/4" to 3-3/8" | 9.456" | 8.456" | 3.75" | 1.3" |

| 03-55M-312 | 55mm | 3-1/2" to 3-5/8" | 9.268" | 8.268" | 3.75" | 1.3" |

| 03-55M-334 | 55mm | 3-3/4" to 3-7/8" | 9.393" | 8.393" | 3.75" | 1.3" |

| 03-55M-400 | 55mm | 4" to 3-1/8" | 9.393" | 8.393" | 3.75" | 1.3" |

| 03-60M-314 | 60mm | 3-1/4" to 3-3/8" | 9.675" | 8.675" | 4.2" | 1.3" |

| 03-60M-312 | 60mm | 3-1/2" to 3-5/8" | 9.675" | 8.675" | 4.2" | 1.3" |

| 03-60M-334 | 60mm | 3-3/4" to 3-7/8" | 9.675" | 8.675" | 4.2" | 1.3" |

| 03-60M-400 | 60mm | 4" to 4-1/8" | 9.675" | 8.675" | 4.2" | 1.3" |

| 03-60M-414 | 60mm | 4-1/4" to 4-3/8" | 9.800" | 8.800" | 4.2" | 1.3" |

| 03-60M-412 | 60mm | 4-1/2" to 4-5/8" | 9.800" | 8.800" | 4.2" | 1.3" |

| 03-60M-434 | 60mm | 4-3/4" to 4-7/8" | 10.670" | 9.670" | 4.2" | 1.3" |

| 03-60M-500 | 60mm | 5" to 5-1/8" | 10.670" | 9.670" | 4.2" | 1.3" |

| 03-65M-314 | 65mm | 3-1/4" to 3-3/8" | 9.800" | 8.800" | 4.2" | 1.3" |

| 03-65M-312 | 65mm | 3-1/2" to 3-5/8" | 9.800" | 8.800" | 4.2" | 1.3" |

| 03-65M-334 | 65mm | 3-3/4" to 3-7/8" | 9.800" | 8.800" | 4.2" | 1.3" |

| 03-65M-400 | 65mm | 4" to 4-1/8" | 9.800" | 8.800" | 4.2" | 1.3" |

| 03-65M-414 | 65mm | 4-1/4" to 4-3/8" | 9.925" | 8.925" | 4.2" | 1.3" |

| 03-65M-412 | 65mm | 4-1/2" to 4-5/8" | 9.925" | 8.925" | 4.2" | 1.3" |

| 03-65M-434 | 65mm | 4-3/4" to 4-7/8" | 10.795" | 9.795" | 4.2" | 1.3" |

| 03-65M-500 | 65mm | 5" to 5-1/8" | 10.795" | 9.795" | 4.2" | 1.3" |

| 03-70M-400 | 70mm | 4" to 4-1/8" | 9.988" | 8.988" | 5" | 1.3" |

| 03-70M-414 | 70mm | 4-1/4" to 4-3/8" | 9.988" | 8.988" | 5" | 1.3" |

| 03-70M-412 | 70mm | 4-1/2" to 4-5/8" | 9.800" | 8.800" | 5" | 1.3" |

| 03-70M-434 | 70mm | 4-3/4" to 4-7/8" | 10.860" | 9.860" | 5" | 2.5" |

| 03-70M-500 | 70mm | 5" to 5-1/8" | 10.670" | 9.670" | 5" | 2.5" |

| 03-70M-514 | 70mm | 5-1/4" to 5-3/8" | 9.925" | 8.925" | 5" | 1.3" |

| 03-70M-512 | 70mm | 5-1/2" to 5-5/8" | 10.795" | 9.795" | 5" | 2.5" |

| 03-70M-534 | 70mm | 5-3/4" to 5-7/8" | 10.795" | 9.795" | 5" | 2.5" |

| 03-70M-600 | 70mm | 6" to 7-1/8" | 10.795" | 9.795" | 5" | 2.5" |

| 03-75M-400 | 75mm | 4" to 4-1/8" | 9.988" | 8.988" | 5" | 1.3" |

| 03-75M-414 | 75mm | 4-1/4" to 4-3/8" | 9.988" | 8.988" | 5" | 1.3" |

| 03-75M-412 | 75mm | 4-1/2" to 4-5/8" | 9.800" | 8.800" | 5" | 1.3" |

| 03-75M-434 | 75mm | 4-3/4" to 4-7/8" | 10.858" | 9.858" | 5" | 2.5" |

| 03-75M-500 | 75mm | 5" to 5-1/8" | 10.670" | 9.670" | 5" | 2.5" |

| 03-75M-514 | 75mm | 5-1/4" to 5-3/8" | 9.925" | 8.925" | 5" | 1.3" |

| 03-75M-512 | 75mm | 5-1/2" to 5-5/8" | 10.983" | 9.983" | 5" | 2.5" |

| 03-75M-534 | 75mm | 5-3/4" to 5-7/8" | 10.795" | 9.795" | 5" | 2.5" |

| 03-75M-600 | 80mm | 6" to 6-1/8" | 10.795" | 9.795" | 5" | 2.5" |

| 03-80M-400 | 80mm | 4" to 4-1/8" | 9.988" | 8.988" | 5" | 1.3" |

| 03-80M-414 | 80mm | 4-1/4" to 4-3/8" | 9.988" | 8.988" | 5" | 1.3" |

| 03-80M-412 | 80mm | 4-1/2" to 4-5/8" | 9.800" | 8.800" | 5" | 1.3" |

| 03-80M-434 | 80mm | 4-3/4" to 4-7/8" | 10.858" | 9.858" | 5" | 2.5" |

| 03-80M-500 | 80mm | 5" to 5-1/8" | 10.670" | 9.670" | 5" | 2.5" |

| 03-80M-514 | 80mm | 5-1/4" to 5-3/8" | 9.925" | 8.925" | 5" | 1.3" |

| 03-80M-512 | 80mm | 5-1/2" to 5-5/8" | 10.983" | 9.983" | 5" | 2.5" |

| 03-80M-534 | 80mm | 5-3/4" to 5-7/8" | 10.795" | 10.795" | 5" | 2.5" |

| 03-80M-600 | 80mm | 6" to 6-1/8" | 10.795" | 9.795" | 5" | 2.5" |

| 03-85M-412 | 85mm | 4-1/2" to 4-5/8" | 10.538" | 9.538" | 6" | 1.3" |

| 03-85M-434 | 85mm | 4-3/4" to 4-7/8" | 10.538" | 9.538" | 6" | 1.3" |

| 03-85M-500 | 85mm | 5" to 5-1/8" | 10.538" | 9.538" | 6" | 1.3" |

| 03-85M-514 | 85mm | 5-1/4" to 5-3/8" | 10.350" | 9.350" | 6" | 1.3" |

| 03-85M-512 | 85mm | 5-1/2" to 5-5/8" | 11.408" | 10.408" | 6" | 2.5" |

| 03-85M-534 | 85mm | 5-3/4" to 5-7/8" | 11.408" | 10.408" | 6" | 2.5" |

| 03-85M-600 | 85mm | 6" to 6-1/8" | 11.220" | 10.220" | 6" | 2.5" |

| 03-90M-412 | 90mm | 4-1/2" to 4-5/8" | 10.538" | 9.538" | 6" | 1.3" |

| 03-90M-434 | 90mm | 4-3/4" to 4-7/8" | 10.538" | 9.538" | 6" | 1.3" |

| 03-90M-500 | 90mm | 5" to 5-1/8" | 10.538" | 9.538" | 6" | 1.3" |

| 03-90M-514 | 90mm | 5-1/4" to 5-3/8" | 10.350" | 9.350" | 6" | 1.3" |

| 03-90M-512 | 90mm | 5-1/2" to 5-5/8" | 11.408" | 10.408" | 6" | 2.5" |

| 03-90M-534 | 90mm | 5-3/4" to 5-7/8" | 11.408" | 10.408" | 6" | 2.5" |

| 03-90M-600 | 90mm | 6" to 6-1/8" | 11.220" | 10.220" | 6" | 2.5" |

| 03-95M-412 | 95mm | 4-1/2" to 4-5/8" | 10.538" | 9.538" | 6" | 1.3" |

| 03-95M-434 | 95mm | 4-3/4" to 4-7/8" | 10.538" | 9.538" | 6" | 1.3" |

| 03-95M-500 | 95mm | 5-1/8" to 5-1/8" | 10.538" | 9.538" | 6" | 1.3" |

| 03-95M-514 | 95mm | 5-1/4" to 5-3/8" | 10.350" | 9.350" | 6" | 1.3" |

| 03-95M-512 | 95mm | 5-1/2" to 5-5/8" | 11.408" | 10.408" | 6" | 2.5" |

| 03-95M-534 | 95mm | 5-3/4" to 5-7/8" | 11.408" | 10.408" | 6" | 2.5" |

| 03-95M-600 | 95mm | 6" to 6-1/8" | 11.220" | 10.220" | 6" | 2.5" |

CERTIFICATES

RINA

BUREAU VERITAS

ABS

vidéos

What is a PSS Shaft Seal ?

Removing the shaft coupling

PSS FAQ

DEALERS

PSS Shaft Seals are available around the world. Use the map below to find the nearest PSS Shaft Seal dealer to you.