HOW DOES IT WORK ?

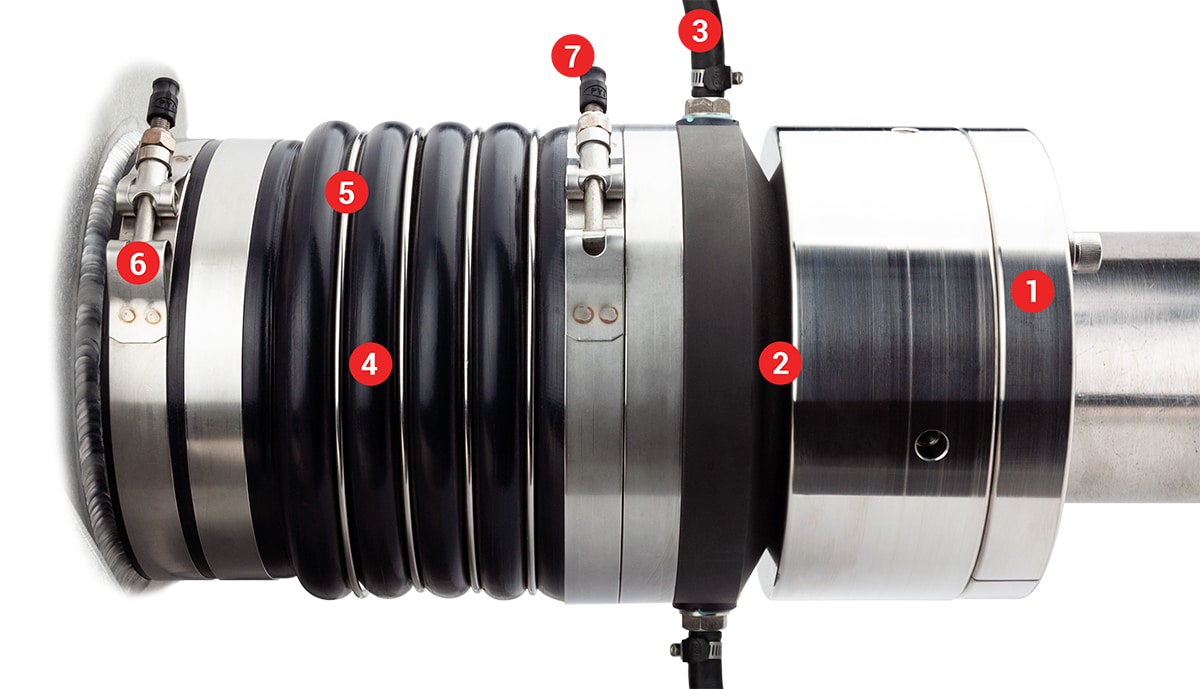

1 This clamp assembly maintains the PSS Type B preload / compression without the need for set screws.

2 A seal is created between the two flat surfaces of the carbon stator and the stainless steel rotor.

3 Water is fed into the PSS Shaft Seal for cooling/lubricating the seal faces on high speed vessels.

4 The stationary carbon stator is attached to the nitrile bellow, which is attached to the stern tube (shaft log)

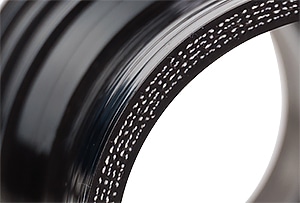

5 Stainless steel rings are fit to the bellow for increased strength, support and durability.

6 Hose clamps secure the PSS Type B Shaft Seal to the stern tube and onto the carbon stator.

7 Hose clamp tail protection, Clamp Jackets.

COMPONENTS

ROTOR

STATOR

BELLOW RINGS

HOSE BARB

BELLOW

ADDED STRENGH

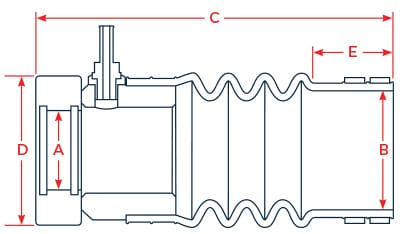

DIMENSIONS

| Part # | Shaft Dia. (A) | Stern Tube Dia. (B) | Uncompressed Length (C) | Approx. Compression | Rotor Diameter (D) | Stern Cuff Length (E) |

|---|---|---|---|---|---|---|

| 02-400-512 | 4" | 5-1/2" to 5-5/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-400-534 | 4" | 5-3/4" to 5-7/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-400-600 | 4" | 6" to 6-1/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-400-614 | 4" | 6-1/4" to 6-3/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-400-612 | 4" | 6-1/2" to 6-5/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-400-634 | 4" | 6-3/4" to 6-7/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-400-700 | 4" | 7" to 7-1/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-414-512 | 4-1/4" | 5-1/2" to 5-5/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-414-534 | 4-1/4" | 5-3/4" to 5-7/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-414-600 | 4-1/4" | 6" to 6-1/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-414-614 | 4-1/4" | 6-1/4" to 6-3/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-414-612 | 4-1/4" | 6-1/2" to 6-5/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-414-634 | 4-1/4" | 6-3/4" to 6-7/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-414-700 | 4-1/4" | 7" to 7-1/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-412-512 | 4-1/2" | 5-1/2" to 5-5/8" | 13.189" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-412-534 | 4-1/2" | 5-3/4" to 5-7/8" | 13.189" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-412-600 | 4-1/2" | 6" to 6-1/8" | 13.189" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-412-614 | 4-1/2" | 6-1/4" to 6-3/8" | 13.189" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-412-612 | 4-1/2" | 6-1/2" to 6-5/8" | 13.189" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-412-634 | 4-1/2" | 6-3/4" to 6-7/8" | 13.189" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-412-700 | 4-1/2" | 7" to 7-1/8" | 13.189" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-434-612 | 4-3/4" | 6-1/2" to 6-5/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-434-634 | 4-3/4" | 6-3/4" to 6-7/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-434-700 | 4-3/4" | 7" to 7-1/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-434-714 | 4-3/4" | 7-1/4" to 7-3/8" | 13.671" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-434-712 | 4-3/4" | 7-1/2" to 7-5/8" | 13.671" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-434-734 | 4-3/4" | 7-3/4" to 7-7/8" | 13.671" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-434-800 | 4-3/4" | 8" to 8-1/8" | 13.671" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-434-858 | 4-3/4" | 8-5/8" to 8-3/4" | 13.671" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-500-600 | 5" | 6" to 6-1/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-500-612 | 5" | 6-1/2" to 6-5/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-500-634 | 5" | 6-3/4" to 6-7/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-500-700 | 5" | 7" to 7-1/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-500-714 | 5" | 7-1/4" to 7-3/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-500-712 | 5" | 7-1/2" to 7-5/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-500-734 | 5" | 7-3/4" to 7-7/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-500-800 | 5" | 8" to 8-1/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-500-858 | 5" | 8-5/8" to 8-3/4" | 13.671" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-512-612 | 5-1/2" | 6-1/2" to 6-5/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-512-634 | 5-1/2" | 6-3/4" to 6-7/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-512-700 | 5-1/2" | 7" to 7-1/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-512-714 | 5-1/2" | 7-1/4" to 7-3/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-512-712 | 5-1/2" | 7-1/2" to 7-5/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-512-734 | 5-1/2" | 7-3/4" to 7-7/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-512-800 | 5-1/2" | 8" to 8-1/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-512-858 | 5-1/2" | 8-5/8" to 8-3/4" | 13.671" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-600-612 | 6" | 6-1/2" to 6-5/8" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-600-634 | 6" | 6-3/4" to 6-7/8" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-600-700 | 6" | 7" to 7-1/8" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-600-714 | 6" | 7-1/4" to 7-3/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-600-712 | 6" | 7-1/2" to 7-5/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-600-734 | 6" | 7-3/4" to 7-7/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-600-800 | 6" | 8" to 8-1/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-600-858 | 6" | 8-5/8" to 8-3/4" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-612-700 | 6-1/2" | 7" to 7-1/8" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-612-714 | 6-1/2" | 7-1/4" to 7-3/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-612-712 | 6-1/2" | 7-1/2" to 7-5/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-612-734 | 6-1/2" | 7-3/4" to 7-7/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-612-800 | 6-1/2" | 8" to 8-1/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-612-858 | 6-1/2" | 8-5/8" to 8-3/4" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

| Part # | Shaft Dia. (A) | Stern Tube Dia. (B) | Approx. Length (C) | Approx. Compression | Rotor Diameter (D) | Stern Cuff Length (E) |

|---|---|---|---|---|---|---|

| 02-100M-512 | 100mm | 5-1/2" to 5-5/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-100M-534 | 100mm | 5-3/4" to 5-7/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-100M-600 | 100mm | 6" to 6-1/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-100M-614 | 100mm | 6-1/4" to 6-3/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-100M-612 | 100mm | 6-1/2" to 6-5/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-100M-634 | 100mm | 6-3/4" to 6-7/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-100M-700 | 100mm | 7" to 7-1/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-110M-512 | 110mm | 5-1/2" to 5-5/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-110M-534 | 110mm | 5-3/4" to 5-7/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-110M-600 | 110mm | 6" to 6-1/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-110M-614 | 110mm | 6-1/4" to 6-3/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-110M-612 | 110mm | 6-1/2" to 6-5/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-110M-634 | 110mm | 6-3/4" to 6-7/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-110M-700 | 110mm | 7" to 7-1/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-115M-512 | 115mm | 5-1/2" to 5-5/8" | 13.314" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-115M-534 | 115mm | 5-3/4" to 5-7/8" | 13.314" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-115M-600 | 115mm | 6" to 6-1/8" | 13.314" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-115M-614 | 115mm | 6-1/4" to 6-3/8" | 13.314" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-115M-612 | 115mm | 6-1/2" to 6-5/8" | 13.314" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-115M-634 | 115mm | 6-3/4" to 6-7/8" | 13.314" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-115M-700 | 115mm | 7" to 7-2/8" | 13.314" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-120M-612 | 120mm | 6-1/2" to 6-5/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-120M-634 | 120mm | 6-3/4" to 6-7/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-120M-700 | 120mm | 7" to 7-1/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-120M-714 | 120mm | 7-1/4" to 7-3/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-120M-712 | 120mm | 7-1/2" to 7-5/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-120M-734 | 120mm | 7-3/4" to 7-7/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-120M-800 | 120mm | 8" to 8-1/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-120M-858 | 120mm | 8-5/8" to 8-3/4" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-130M-612 | 130mm | 6-1/2" to 6-5/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-130M-634 | 130mm | 6-3/4" to 6-7/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-130M-700 | 130mm | 7" to 7-1/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-130M-714 | 130mm | 7-1/4" to 7-3/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-130M-712 | 130mm | 7-1/2" to 7-5/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-130M-734 | 130mm | 7-3/4" to 7-7/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-130M-800 | 130mm | 8" to 8-1/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-130M-858 | 130mm | 8-5/8" to 8-3/4" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-140M-612 | 140mm | 6-1/2" to 6-5/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-140M-634 | 140mm | 6-3/4" to 6-7/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-140M-700 | 140mm | 7" to 7-1/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-140M-714 | 140mm | 7-1/4" to 7-3/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-140M-712 | 140mm | 7-1/2" to 7-5/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-140M-734 | 140mm | 7-3/4" to 7-7/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-140M-800 | 140mm | 8" to 8-1/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-140M-858 | 140mm | 8-5/8" to 8-3/4" | 13.671" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-150M-612 | 150mm | 6-1/2" to 6-5/8" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-150M-634 | 150mm | 6-3/4" to 6-7/8" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-150M-700 | 150mm | 7" to 7-1/8" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-150M-714 | 150mm | 7-1/4" to 7-3/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-150M-712 | 150mm | 7-1/2" to 7-5/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-150M-734 | 150mm | 7-3/4" to 7-7/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-150M-800 | 150mm | 8" to 8-1/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-150M-858 | 150mm | 8-5/8" to 8-3/4" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-165M-700 | 165mm | 7" to 7-1/8" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-165M-714 | 165mm | 7-1/4" to 7-3/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-165M-712 | 150mm | 7-1/2" to 7-5/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-165M-734 | 150mm | 7-3/4" to 7-7/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-165M-800 | 150mm | 8" to 8-1/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-165M-858 | 150mm | 8-5/8" to 8-3/4" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

CERTIFICATES

RINA

BUREAU VERITAS

ABS

vidéos

What is a PSS Shaft Seal ?

Removing the shaft coupling

PSS FAQ

DEALERS

PSS Shaft Seals are available around the world. Use the map below to find the nearest PSS Shaft Seal dealer to you.